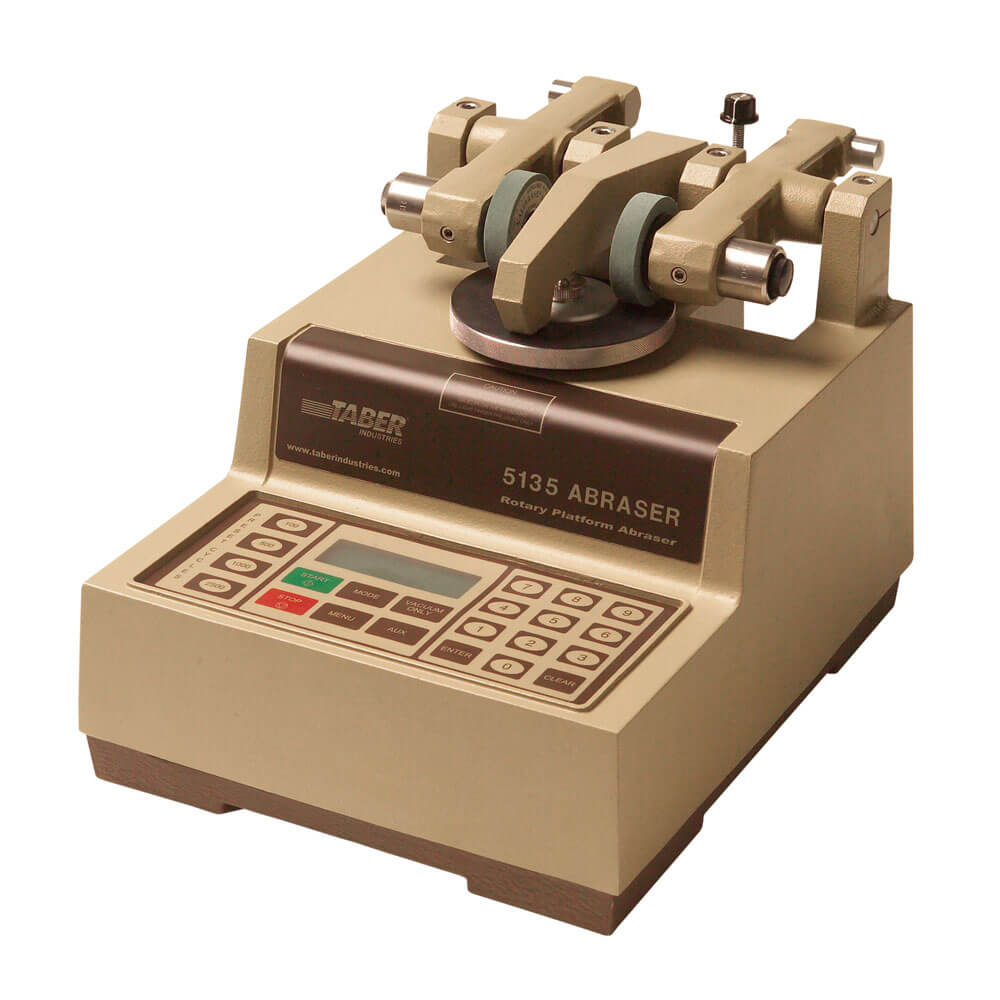

5135 & 5155 Taber® Rotary Abrasers

The Taber® Rotary Abraser is an industry standard used in the wear and durability testing and is available with either a single test head or dual testing heads, which allows the user to test two different or identical materials simultaneously.

Used primarily in the testing of ceramics, plastics, textiles, metals, leather, rubber and painted, lacquered and electroplated surfaces, accelerated wear test procedures have also been written into many test specifications including ASTM, ISO, TAPPI and DIN – as well as automotive manufacturing procedures around the world.

Choose from a wide variety of abrading wheels and abraser accessories to simulate real-life wear conditions.

Features :

- Platform speeds 60 and 72rpm

- Balanced, calibrated arms and wheel mounts

- Vacuum system with precision height adjustment

- Sealed aluminium housing with membrane control panel and digital display

Taber® Abrading Wheels

Taber® Abrading Wheels are available in five levels of abrasiveness to suit a wide range of material testing applications.

Wool, felt or plain rubber wheels test delicate materials or abrasiveness of materials such as dental powders.

Wheels featuring abrasive particles in a resilient matrix of rubber or a hard matrix of vitrified clay are suitable for stiffer materials.

- Calibrase® : resilient abrasive wheel – rubber and aluminium oxide

- Calibrade®: a non-resilient abrasive wheel – vitrified clay and silicon carbide

- Plain Rubber: contains no abrasive particles unless used with sandpaper strips

- Tungsten Carbide: severe cutting and tearing action with helical teeth for use on resilient materials such as rubber, leather and floor coverings

Please contact us here to make an enquiry.